COANDA Effect Screens

Angled Wedge Wire Profiles to create Coanda Effect Screens

Coanda screens are tilted profile wire bar screens. The shape of the screens allows the screens to remain clean with little or no mechanical cleaning. The operation is enhanced by the Coanda Effect as the screens catch only the bottom layer of water. The tilted profile wires of the Coanda Screen slice off thin layers of water, allowing debris and fish to pass safely over the screen as water falls through the screen.

Coanda Screen Technology

Coanda Screens are positioned on the downstream face of an intake weir. An ogee shaped acceleration plate delivers the flow at the precise angle and velocity required by the separation area of the screen. The Coanda effect promotes consistent contact with the screen surface. Wedge Wire placed at precise and consistent slot gap tolerance screens away debris and particles.

The screened water flowing through the open area collects in a chamber beneath to be distributed to associated pipelines. The specified tilt angle of the wedge wire has an additional shearing effect increasing throughput.

Precision Engineering & Fabrication

Coanda Screens can be produced in 304 or 316 grade stainless steel. The uniformity and precision slot gap of the screening area ensures high capacity throughputs and accurate removal of debris. Gap Technology wedge wire screens are utilised and trusted by clients in over fifty countries worldwide.

Each Coanda Screen can be produced to bespoke dimensions and specifications with optional slot gap widths, wire profiles and inclinations to maximise performance.

Key benefits of Coanda Screens include

- A reliable supply of screened water which increases hydro plant operating time, output and efficiency.

- Self-cleaning properties result in a largely maintenance free operation saving time and associated costs.

- Slot gap sizes can be specified to screen debris from diameters as fine as 0.2mm up to a width of 2mm.

- No mechanical moving parts eliminates the need for costly maintenance and a power supply.

- Coanda Gap’s modular construction ensures ease of assembly

- Highly resilient screen construction is resistant to abrasive material and corrosion.

- Proven operational performance even at low temperatures in some of the world’s coldest environments without freezing.

- Trusted in fisheries conservation areas not to cause harm to fish stocks.

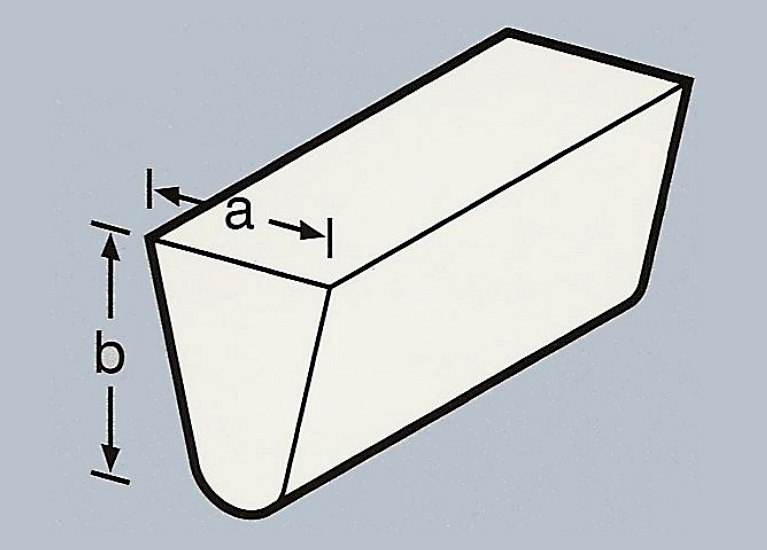

Sb Welded Wedge Profile

The Sb range of welded wedge wire is our most frequently used profile in this application. It offers minimum resistance to passing liquids and fine particles to alleviate potential blinding.

Gap Technology boasts the largest range of Wedge Wire SB Profiles within the UK, available in a range of high grade stainless steel materials and finishes with precision forming, welding, specialist finishing and acid cleaning to meet stringent standards.

The data table provide theoretical values for the Wedge Wire SB Profile only, as support rod type and pitch may vary in selected applications. These welded wedge wire sb profile can also be manufactured with an inclined screening surface where required.

| PROFILE | DIMENSIONS | SLOT GAP (Millimetres) | |||||||||||||||||||

| A | B | 0.50 | 1.00 | 1.50 | 2.00 | 2.50 | 3.00 | ||||||||||||||

| 18 SB | 1.50 | 2.50 | Open Area % | 25.00 | 40.00 | 50.00 | 57.10 | 62.50 | 66.67 | ||||||||||||

| Kg/m2 | 13.56 | 11.56 | 10.22 | 9.26 | 8.56 | 7.42 | |||||||||||||||

| 22 SB | 1.80 | 3.70 | Open Area % | 21.70 | 35.70 | 45.50 | 52.60 | 58.10 | 62.50 | ||||||||||||

| Kg/m2 | 19.36 | 16.58 | 14.63 | 13.18 | 12.07 | 11.13 | |||||||||||||||

| 28 SB | 2.20 | 4.50 | Open Area % | 18.50 | 31.30 | 40.50 | 47.60 | 53.20 | 57.69 | ||||||||||||

| Kg/m2 | 23.10 | 20.07 | 17.89 | 16.22 | 14.86 | 13.55 | |||||||||||||||

| 34 SB | 2.80 | 5.00 | Open Area % | 15.20 | 26.30 | 34.90 | 41.70 | 47.20 | 51.72 | ||||||||||||

| Kg/m2 | 27.96 | 24.81 | 22.36 | 20.46 | 18.88 | 17.95 | |||||||||||||||

| 42 SB | 3.40 | 6.50 | Open Area % | 12.80 | 22.70 | 30.60 | 37.00 | 42.40 | 46.88 | ||||||||||||

| Kg/m2 | 33.20 | 29.93 | 27.33 | 25.19 | 23.38 | 19.08 | |||||||||||||||

Materials: Stainless Steel AISI 316, 316L

Comprehensive Service

Our specialist team of coanda screening experts can advise and assist with…

- Screen selection and bespoke design.

- Turnkey installations.

- Retrofit and replacement screen solutions.

- If you send us your concrete chamber drawing, we will make the screens bespoke to suit your needs.

Associated Downloads available

COANDA SCREENS

Precision manufactured Coanda Screens from Gap Technology / File Size: 1,956 KB

COANDA SCREENS

Typical General Arrangement for the Coanda Screen / Gap Technology / File Size: 5,044 KB

More information / Enquiries

For more information and general enquiries on our coanda screens / coanda screen technology, or any of our associated wedge wire products and services, please complete your details via our Enquiry Form.

Alternatively, you can contact us directly by telephoning 01777 710 710