PASSIVE Water Intake Screens

Water Intake Screens and Treatment in rivers and lakes

Passive Water Intake Screens admit water through the intake point at a low, uniform velocity. Water passes through these screens leaving debris and aquatic life to remain in the water. Renowned for their reliable large throughput, water intake screens are installed in lakes and rivers, used for feeding power and desalination plants and water production plants for industrial uses such as paper mills and farm-produce plants.

Submersible Static Filter

The Gap intake screen is a submersible static filter. Filtering surfaces and body are manufactured from metal alloys, eliminating the risk of corrosion.

They have no environmental impact being totally submerged so they are not visible on the landscape. Because of their very low entrance velocity, wildlife can easily escape the screen surface. Added to this, the air back wash cleaning system is non-polluting as it uses an oil-free compressor.

Their only running cost is filling the air receiver with compressed air prior to back-washing which works by injecting the compressed air into the water intake screen enabling debris to be expelled from the filter surface into the aquatic environment.

Photo Gallery

Gap Technology are able to offer complete set-up services including backwash systems for our passive water intake screens.

Contact Us for full details and enquiries

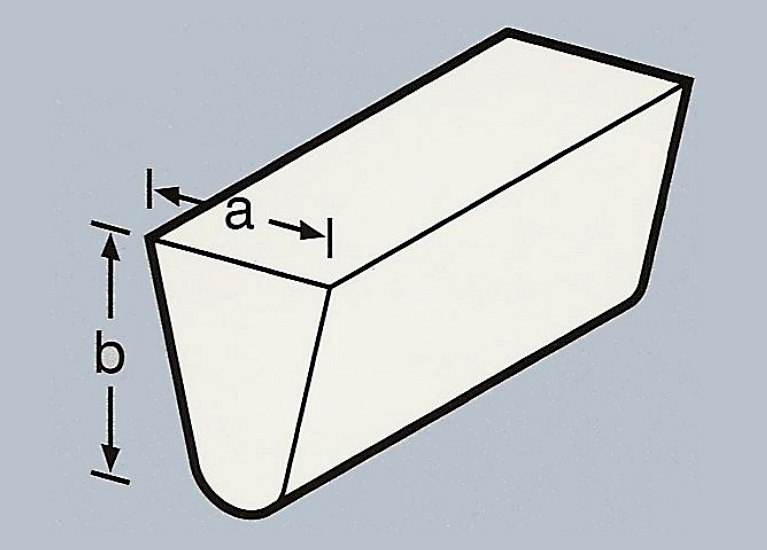

Sb Welded Wedge Profile

The Sb range of welded wedge wire is our most frequently used profile in this application. It offers minimum resistance to passing liquids and fine particles to alleviate potential blinding.

Gap Technology boasts the largest range of Wedge Wire SB Profiles within the UK, available in a range of high grade stainless steel materials and finishes with precision forming, welding, specialist finishing and acid cleaning to meet stringent standards.

The data table provide theoretical values for the Wedge Wire SB Profile only, as support rod type and pitch may vary in selected applications. These welded wedge wire sb profile can also be manufactured with an inclined screening surface where required.

| PROFILE | DIMENSIONS | SLOT GAP (Millimetres) | |||||||||||||||||||

| A | B | 0.50 | 1.00 | 1.50 | 2.00 | 2.50 | 3.00 | ||||||||||||||

| 18 SB | 1.50 | 2.50 | Open Area % | 25.00 | 40.00 | 50.00 | 57.10 | 62.50 | 66.67 | ||||||||||||

| Kg/m2 | 13.56 | 11.56 | 10.22 | 9.26 | 8.56 | 7.42 | |||||||||||||||

| 22 SB | 1.80 | 3.70 | Open Area % | 21.70 | 35.70 | 45.50 | 52.60 | 58.10 | 62.50 | ||||||||||||

| Kg/m2 | 19.36 | 16.58 | 14.63 | 13.18 | 12.07 | 11.13 | |||||||||||||||

| 28 SB | 2.20 | 4.50 | Open Area % | 18.50 | 31.30 | 40.50 | 47.60 | 53.20 | 57.69 | ||||||||||||

| Kg/m2 | 23.10 | 20.07 | 17.89 | 16.22 | 14.86 | 13.55 | |||||||||||||||

| 34 SB | 2.80 | 5.00 | Open Area % | 15.20 | 26.30 | 34.90 | 41.70 | 47.20 | 51.72 | ||||||||||||

| Kg/m2 | 27.96 | 24.81 | 22.36 | 20.46 | 18.88 | 17.95 | |||||||||||||||

| 42 SB | 3.40 | 6.50 | Open Area % | 12.80 | 22.70 | 30.60 | 37.00 | 42.40 | 46.88 | ||||||||||||

| Kg/m2 | 33.20 | 29.93 | 27.33 | 25.19 | 23.38 | 19.08 | |||||||||||||||

Materials: Stainless Steel AISI 316, 316L / Super Duplex, Copper & Specialist Alloys

Comprehensive Service

Our specialist team of coanda screening experts can advise and assist with…

- Screen selection and bespoke design.

- Turnkey installations.

- Retrofit and replacement screen solutions.

Associated Downloads available

PASSIVE WATER INTAKE SCREENS

Wedge Wire Water Treatment and Clarification Applications / File Size: 1,130 KB

PASSIVE WATER INTAKE SCREENS

Typical General Arrangement / Gap Technology / File Size: 2,376 KB

QUESTIONNAIRE

Passive Water Intake Screens Questionnaire for Quotation Requests / File Size: 267 KB

More information / Enquiries

For more information and general enquiries on our passive water intake screens / water screening technology, or any of our associated wedge wire products and services, please complete your details via our Enquiry Form.

Alternatively, you can contact us directly by telephoning 01777 710 710